10% Off Sitewide Sale + Free Shipping No Minimum*

The Many Uses of Pool Putty

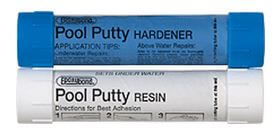

Pool Putty has been around for as long as I can remember. An essential ingredient in any poolman's arsenal for pool repair, pool putty can be put to a myriad of uses. There are 3 brands of pool putty available.

Easy to use, just mix the two part epoxy together, equal parts of resin and hardener, and an exothermic chemical reaction begins immediately. Knead the two parts together by hand (a little pool water helps), and you have a waterproof, moldable substance that can be used to patch, seal or repair many items around the pool. Here's some ideas for using pool putty around your pool.

Skimmer Repairs: On plastered, concrete pools, the skimmer can become an easy source of leaks. During construction, the skimmer is tied into the back of the pool wall using rebar, concrete and plaster. Over time, with normal expansion and contraction of the pool wall and pool deck, separation of the skimmer and the pool wall can occur.

Leaning over the edge of the pool, or looking into the skimmer throat from inside the pool, inspect the bottom and sides - where the skimmer is connected to the pool wall. You can use a dye syringe to test the skimmer for leaks, or visibly note the cracked plaster between pool and skimmer. Small bits of debris, sucked into the crack, can also tip you off to the presence of a leak. Remove any loose or cracked material, or chip off previous pool putty repairs with a small, sharp flathead screwdriver. Surface should be free of algae and loose debris for the best bond.

After mixing equal parts of pool putty together, roll the mixture between your hands to make a "snake". Place the putty into the junction of the pool skimmer and pool wall, pushing into the area firmly to fill any cracks or voids. If above the water line, use a bit of pool water to help smooth and form the putty. This will fix the pool leak immediately, at least until significant movement occurs again, at which point your pool putty repair will need to be re-done.

Another common skimmer problem occurs when the side walls of the skimmer become cracked. Cracked skimmers usually occur from deck movement or pressure surrounding the outside of your skimmer. Cracks in the side of your pool skimmer can also easily be repaired with a little pool putty. Make a thin, smooth repair, so as to not interfere with removing the skimmer basket, or the movement of your skimmer weir.

Using pool putty on skimmers is very common. If your pool contractor tells you to replace the skimmer instead, there should be a good reason to. Pool Putty repairs can last many years, or can be redone as needed. Replacing the skimmer on an inground pool is a big job, and will cost at least $1000!

Pool Pump Repairs: When pool pumps overheat, the MTA (Male Threaded Adapter) that is screwed into the front of the pump can shrink, and allow air to enter the pump basket at this point. Air is the path of least resistance, and it's easier for your pool pump to draw air than it is to draw water, especially if your pump is mounted above the water level.

If it is not clearly evident that the MTA is leaking, (and you have ruled out loose pump lid, or drain plug) you can test this fitting for air leaks, by wrapping a piece of duct tape tightly around the threads of the fitting, and see if the air leak stops. Now, the proper repair would be to cut out the MTA fitting, and replace it, however this can sometimes be difficult to do, or inconvenient at the time. In comes pool putty to save the day! With the pump running, roll up a putty snake, and press into the junction of the MTA and the threaded port on the front of the pump. Use a good quantity of pool putty and lots of water to create layers, building up as you go - using about 1/3 of a tube.

Leave the pump on for 24 hours after making the repair, so the putty has time to set. Adding a small amount of heat to the mixture can accelerate the cure time, or you can also use Leakmaster Quick Set Putty by Anderson. A unique "one-stick", with the resin wrapped by the hardner, makes for more accurate mixtures. Shutting off the pump before it has cured completely will "blow-out" the repair.

Pool Tile Repairs: I would prefer to replace pool tiles that have fallen off with a Thinset mortar and underwater tile grout. But, in a pinch - pool putty can be used to stick stray tiles back onto the wall. Mix up the pool putty, use lots of water to make it gooey, and make a flat shape, 1/8" or less. Stick onto the back of the tile, and press the tile firmly in place. Use some putty in between the tiles to help secure it in place. Again, this is a shortcut, and only useful for very small repairs. For information on proper pool tile repair, see our recent blog post on How to Repair Pool Tile.

Pool Light Leaks: The conduit, or pipe that connects from the pool light niche and the light junction box can become cracked from movement or freezing, and can become a source of leaks in an inground pool. Many pool guys will use pool putty to make a conical seal around the light cord - at the point where it enters the conduit. Again, this is a convenient method, used when one doesn't have a Light Cord Stopper handy, or would prefer not to rip up the concrete deck to replace the broken conduit (uggh). Leave the pool light undisturbed for 24 hours before reinstalling the light into the niche, to allow the putty to set up. Using pool putty on a leaking pool light is preferable to using silicone, which can be difficult to remove when replacing the pool light.

Oh, what else - It can also repair small cracks in plastic pool steps, ladder treads or pool slides. I wouldn't use it for vinyl liner repair, opting for a vinyl patch kit instead. It also is ineffective at stopping "pressure-side" leaks, or leaking filters or anything under pressure. It will slow the leak perhaps, but won't be able to repair pipes or equipment under pressure. More suitable for air leaks, before the impeller. Neatly patches up anything plastic or concrete. Once dry, pool putty is paintable, sandable, drillable and removable. It can save time and effort in many ways.