10% Off Sitewide Sale + Free Shipping No Minimum*

Size and Selection of Swimming Pool Pumps

The first thing you need to know is that not all horsepowers are equal. Every pump has different flow characteristics, and the flow rate will vary by manufacturer and model.

But the question cannot be answered without some other key insights, namely your Pool Type, Turnover Rate, Filter Design Flow Rate and estimated Resistance, in Feet of Head.

What's Your Pool Type?

Above ground or in ground? Aboveground pool pumps are meant to operate below the water level, on the ground next to the pool. Inground pumps are "self-priming" and can lift water several feet.

Simple or Complex Pool? A small pool with 1 or 2 skimmers and a main drain can use a smaller pump, but pools with attached spas, waterfalls, solar heaters or built in cleaners may need a larger pump.

Turnover Rate?

The Turnover Rate is the time it takes for all of the water in the pool to pass through the filter. An 8-hour turnover rate is considered standard.

Pool Volume in Gallons ÷ Turnover Rate in Minutes = Flow Rate

The formula for Turnover requires that you know your pool size - in gallons. If you have paperwork from your pool builder, this may list the amount of gallons in the pool. If not, break out the calculator, and a measuring tape, if needed.

- Round Pools - Diameter (ft.) X Diameter (ft.) X Average Depth (ft.) X 5.9 = Total Pool Gallons

- Oval Pools - Length (ft.) X Width (ft.) X Average Depth (ft.) X 6.7 = Total Pool Gallons

- Rectangle Pools - Length (ft.) X Width (ft.) X Average Depth (ft.) X 7.5 = Total Pool Gallons

Average depth is calculated by adding the deepest part of the pool to the shallowest part of the pool, and dividing by 2. For instance, if the shallow end is 3' deep, and the deep end is 8', the average depth is 5.5. (3+8 / 2 = 5.5)

Sample Desired Flow Rate calculations, based on an 8 hour (480 minutes) turnover rate:

10,000 (gals) ÷ 480 (mins) = 21 GPM

25,000 (gals) ÷ 480 (mins) = 52 GPM

35,000 (gals) ÷ 480 (mins) = 73 GPM

Pool Filter Design Flow Rate?

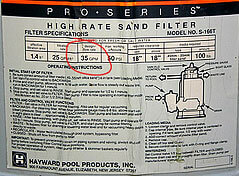

Every pool filter is designed to work best with a certain flow rate of water. If the filter design flow rate is exceeded, it results in poor filtration and filter damage. Lower flow rates do not generally pose a problem, however.

Larger pool filters with more surface area will have higher design flow rates, but every pool filter is different, from 30 gpm to 150 gpm, depending on size and type of pool filter.

Find your Design Flow Rate on the pool filter label, owner's manual, spec sheet or brochure. You can also find this Performance Data listed on our pool filters pages.

Now that you know your Pool Type and your particular pool filter's Design Flow Rate, you are halfway to finding the perfect pump for your pool!

Estimated Resistance?

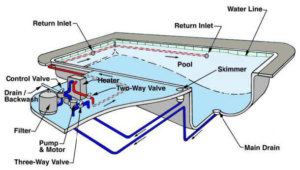

OK, here's where it gets a bit tricky, stay with me... Every pool system has a total resistance that the pump must overcome. The water has to be pulled and pushed through pipes that bend and twist and it's forced through impellers and filters, squeezed through heaters and valves, as well as lifted vertically, from the water level to the pump level. The amount of lift, and all of the pipes, fittings and equipment adds-up to the Total Resistance, measured in Feet of Head.

A simple pool with one skimmer and no heater has a fairly low resistance level, in the 15-20 ft/hd (Feet of Head) range. Add another skimmer, a heater and maybe a spa and more complex pools can be much higher, in the 45-60 ft/hd range. Most inground pools probably fall in the 25-45 ft/hd range.

Total Resistance is made up of all the pipe lengths, turns of the pipe, and all of the equipment that the pump must pull and push water through. Resistance is measured in Feet of Head. To calculate the system resistance, add together these two sums:

- Multiply the clean filter pressure by 2.31 to measure resistance after the pump

- Multiply the pump vacuum by 1.13 to measure resistance before the pump

- Add the two together to compute the total resistance in the system.

Now, most pool owners don't have a vacuum gauge installed before the pump. If you can get of a vacuum gauge (not a pressure gauge), unscrew the front pump drain plug, and thread the vacuum gauge in its place. Turn the pump on and take your reading.

In the absence of a vacuum gauge, you can estimate the suction side vacuum to be something close to 1/3 of the pressure side reading. For example, if your filter pressure x 2.31 = 30, assume that the vacuum reading would equate to 10 ft. of head. Total resistance = 40 ft. of head.

Another way to calculate the suction side resistance, in the absence of a vacuum gauge, is to add up all the bits of pipe and valves before the pump.

- For each 1.5 in. skimmer or main drain, add 2 ft. of head, or 1 ft., if the piping is 2 in. diameter.

- For each 10 feet of 1.5 in. pipe used, add 1 ft. of head, or .5 ft. for each 10 foot run of 2 in. pipe.

- For each 90 degree fitting or valve between the pool and the pump, add 1 ft., or 0.5 ft. for 2 in. pipe.

- For a check valve installed before the pump, add 2 ft. of head.

To roughly calculate the amount of resistance, measured in feet of head, that your pump must overcome, here's a rough approximation method that can be used. Add up all of these resistances to find the total resistance in your system.

Pool Filter - 10 ft

Pool Heater - 10 ft

Pool Cleaner - 10 ft

Pool Piping - 1 ft per 10 feet

90 degree fittings - 1 ft each

Inline Chlorinator or Purifier - 2 ft

Directional Valves - 1 ft each

Skimmers & Drains, 2 ft each

Wall Returns, 2 ft each

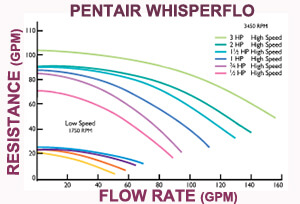

Add these all up, to calculate the total feet of head measurement that your new pool pump must overcome. Then - refer to the manufacturer's website, and look for an image or a link to the Pump Performance Curve for the particular swimming pool pumps you are interested in.

It's an important part of the pool pump selection process, because you want to match the pump to both Design Flow Rate and the amount of Resistance it has to overcome.

We use pump flow curves, or pump performance charts to find the Sweet Spot, where Resistance and Design Flow Rate intersect.

For example, the SPX2610X15 will pump 90 gpm at 30 ft of head, with a clean filter and baskets. On the other hand, a Whisperflo 1-HP (purple line) will pump 80 gpm at 60 ft of head, as shown right.

Bringing it All Together

The best pool pump for you then, is that particular pump that can deliver the flow rate to match your pool filter's design flow rate while overcoming the resistance in your system.

That may be the exact same pump that you are replacing. Unless you had real performance problems with your pool pump, the best pump for you may be the same make, model and horsepower pump.

Bigger is not Better! If two pump curves come close, choose the smaller pump. When it comes to pool pumps people tend to think bigger is always better. Indeed, this is not true with pool pumps. A larger pump will cost more money to operate and if too large - it will start to cavitate, making lots of noise, and overworks the motor. Pool pumps that are too large also compromise filtration and can even damage a filter that is too small.

The same pool pump will also match up to the plumbing pipes, but a different pump will have a slightly different height and depth where the pipes connect.

Another option with less math involved, is to buy a variable speed pool pump. You can set multiple speeds to match your existing equipment, and at the same time cut your electrical usage in half. Prices on VS Pool Pumps have come down to the $750 range.

One More Tip: Remember that not all horsepower pumps are equal. Every pump, regardless of horsepower, has it's own flow rate. A WhisperFlo 1 hp for example, can produce nearly double the flow rate of the Super Pump 1 hp; and that's not always a good thing! Don't oversize the pool pump - you'll save energy, wear and tear and filter the water more effectively.