10% Off Sitewide Sale + Free Shipping No Minimum*

Swimming Pool Plaster Options

Gone are the days of plaster only available in white. Today's plastering companies are offering not only colored additives, but colored aggregates to add visual interest and greater durability.

Your local pool plastering companies may not offer all of these options; some types of plaster are regional offerings.

When Should a Pool be Replastered?

Pool plaster (also called whitecoat or marcite) can last many years before the erosive effects of water and chemicals begin the degrade the surface. The surface eventually becomes rough, and stains become more difficult to remove.

Plaster is the waterproof coating that is spread on top of the gunite or shotcrete shell of your pool. It is meant to degrade very slowly, although corrosive water will affect its appearance and surface softness.

There are really only two reasons for replastering your swimming pool.

Aesthetic reasons to replaster the pool: The look and feel of your pool plaster. Acid washing can remove stains, but this can only be done so much. Pool plaster is a natural product, and preventing stains can almost be impossible. I have often been one to suggest a dose of tolerance with regard to pool stains, but some pool owners are very particular about the look of the pool "especially at night, with the lights on," they say. Over time, any plaster pool will become stained and become rough. When it becomes very rough, the kids end up with "pool toe," and etched surfaces catch dirt and form a nice home for algae to grow.

Structural reasons to replaster the pool: Trick title, because plaster is not "structural," but it is the waterproof layer between the pool water and the shell of the pool. Most plastered pools are made of gunite, or shotcrete. Some older pools were made with poured concrete walls or even cinder blocks. All of these materials are porous and will "weep" water through them. Applying the plaster coating on top keeps the cement beneath, and any reinforcement steel (rebar) protected from the effects of water. Plaster is the waterproofing layer that is important to the integrity of an inground pool structure.

Patching pool plaster: If you have bare spots where the gunite beneath is showing through, this is of concern. You can patch small areas with EZ Patch pool plaster repair, even underwater. Spots at the tile line or inside the skimmer can also be patched easily to protect the concrete beneath the plaster. Plaster is fairly translucent in thin layers, so if you see dark areas in your plaster, this could be the gunite showing through, giving an indication that this area may need patching.

Pool Plaster Additives

Pool plaster is a mix of white portland cement and marble dust. It is called marcite in some parts of the country, whitecoat in others, or just pool plaster. The two components are mixed together with water and bonding additives, sprayed on the prepared surface and troweled smooth.

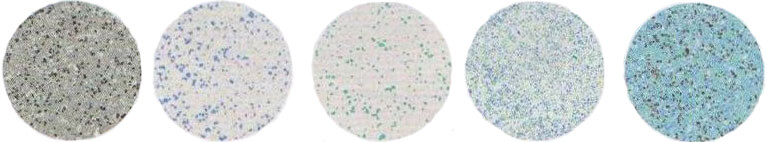

Colors: Pool plaster can be dyed any color by the use of colorants added to the mix. Lamp black dye, in different amounts, can produce shades from light gray to dark black. Hues of blue and red can also be easily and cheaply added to the marcite mix.

The problem with colored plaster is that the color may not be uniform. Variations in hue can occur, and it's common for a colored plaster pool to develop a whitish haze over time. This is normal; however, on white plaster, a white haze is not noticeable.

Nonetheless, adding a color pigment to white pool plaster can produce dramatic results, with French Gray and Federal Blue being the top requested colors.

Quartzite: Colored quartz chips or more basically ceramic coated sand can be added to the plaster mix to create visual interest, colors and a more durable product. Quartz and silica are considerably harder than marble and are more resistant to chemical deterioration and the effects of being submerged in water.

Colored quartz additives are very flat and smooth, and the finished surface is likewise. The colors or specks help to hide surface imperfections and can also make dirt and debris less visible on the pool floor.

Pozzolans: This additive dramatically improves the performance of pool plaster, but you won't know it's there. It doesn't change the color or texture of the plaster. What it does is help preserve your plaster and protect it from etching and mottling. It does this by locking up calcium hydroxide and preventing its reaction with other compounds. The result is a longer lasting, smoother finish.

Silicone Shield: Another additive that is used to extend the lifespan and durability of pool plaster, Silicone Shield is used to "waterproof" your plaster. The product claims to reduce staining, chemical deterioration and solubility of the plaster, by essentially locking out water like a shield of silicone.

Exposed Aggregates

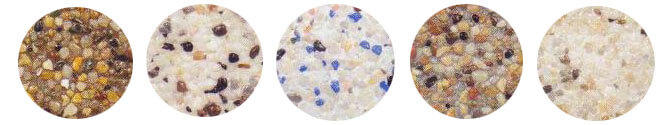

PebbleTec brought the idea from Australia. Using pea gravel-sized river pebbles started as the best way to install a beach front entry, without waterline staining. It's called "exposed" aggregate because after application, a thin top layer is removed to expose the aggregate, or the tiny, colored pebbles.

Other pebble products such as Pebble Sheen, Fina and River Rok are available to plasterers. These create a smooth surface, although somewhat more "bumpy" than other pool surface types. The pebbles have a much higher resistance to water and chemicals, and they typically last much longer than regular pool plaster.

Beadcrete is another Australian product, using tiny glass beads set in a polymer modified mortar. It's very reflective and slip resistant. More chemically resistant than marcite, or marble dust pool plaster, it should be longer lasting as well.

If all of these choices are overwhelming, you can always just go with white plaster again! It's not quite as durable as the other pool surfaces with a greater amount of surface aggregate, and it is more susceptible to visible imperfections and staining. White pool plaster is, however, the most affordable plaster option you can buy.

How About Tile?

Tile has been used for thousands of years, in fountains, baths and early swimming pools. Tiling an entire pool, especially using glass tile, is out of reach for most pool owners, who can instead add trim tile on the steps or around a spa, or tile mosaics of mermaids or sea life.

Complete tile surfaces are primarily used on high-end pool or fountain projects, and it can add 50 percent to the cost of pool construction. It's a project that can take several weeks to complete, but the results can be breathtaking.

Tile used is normally a 1-inch tile, which will bend around curves in the pool wall and floor better than larger tiles. A pool with more square or angular surfaces is easier to tile than one with a lot of floor curves and coves.

Tile surfaces are durable and easy to keep clean, although your grout is susceptible to staining and can be a home for algae if not kept clean. But at least you won't need to plaster the pool!

How to Replaster a Pool

Call three plastering companies in your area to give competing quotes. Be sure to ask about the startup procedures. Don't try this at home; there really is an art and a science to plastering pools properly. Small areas can be patched or touched up, but an entire pool? Done improperly and you risk bond failure, crazing, shading and etching. All sorts of things can go wrong with trying to plaster your own pool. It's tempting when you see the cost of a new whitecoat ($4,000-$6,000), but it's too much of an art and science, skill and timing.

A small fountain can be done, if you are an experienced concrete person, maybe even a very small pool, but medium to large pools have to be plastered quickly. I have watched many plaster crews in action, and they always amaze me. It takes them four hours, start to finish, on a 40,000-gallon pool (just the plastering part, not including the prep work). They run a full plastering rig (truck), with five experienced crew members.

The best time to replaster is when weather is somewhat cool and humid. If done during high temperature times of the year, this can causing premature drying before the pool has a chance to fill fully.